Kai Friebel

Industrial Leak Detection Technology

Automotive Industry

Solutions for your Branch | Automotive Industry

For your quality assurance in the automotive sector, we will

develop a machine in line with your requirements. As of today, we

have successfully put 250 machines in operation at our customers.

With different testing systems, optimized to each application, our

customers verify e. g. pneumatic spring systems, refrigeration

lines, heat exchangers and transmissions.

Our Scope of Supply includes:

- MacPherson Strut Unit

- Transmissions

- Refrigeration Lines

- Aluminum Wheels

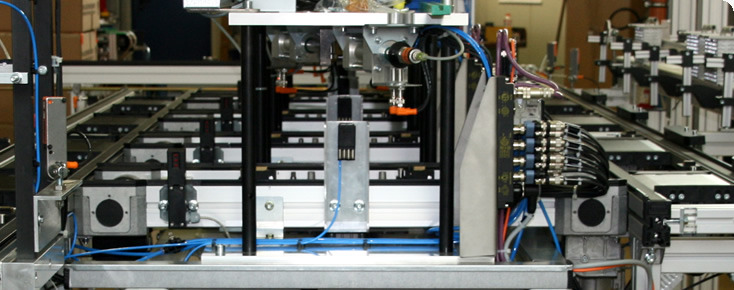

Test Unit

For the manufacturers of air suspension systems for cars, we developed a leak detection machine for testing air suspensions. The semi automatic leak detection machine is fed manually with the test pieces. The low number of test pieces and their unwieldy shapes would be uneconomically for an automatic feeding system. This leak detection machine uses the helium test gas method, which is measured with the mass spectrometer. The test gas is recovered after the testing procedure is completed.

Test Piece

Test piece is the suspension cylinder of the air suspension system. The test gas is pumped into the cylinder and a vacuum is created on the outside of the cylinder. The Leak Detection System verifies the tightness of the cylinder towards the outside.

- Leak Rate: Range 10E-5 ccm/sec

- Production Cycle: parts/hour

- Test piece volume: 10 liter

- Test Pressure: 12 bar

- Test Gas: Helium-Air

Test Unit

Automobile transmission makers use our leak detection machine to verify the transmission housing will not leak any transmission fluid. The lower requirements for tightness allow testing with „ambient air.“ The mass spectrometer detects the test gas (ambient air). Due to low production numbers and the unwieldy test piece, vdh designed a semi-automatic leak detection machine, which means the feeding of the test pieces into the tester is carried out manually.

Test Piece

Test piece is the transmission housing. It consists of three chambers, which are connected to each other. During the test cycle, each chamber is tested individually and after that the entire chamber system is tested for tightness. For this, the chambers are sealed against each other within the housing. Vacuum is created in the chambers with certain valve switchings and the air entry from the outside is measured.

- Leak Rate: Range 10E-1 ccm/sec

- Production Cycle: 60 parts/hour

- Test piece volume: 3 liter

- Test Pressure: 1 bar

- Test Gas: Air

Test Unit

vdh developed a leak detection machine for manufacturers of refrigeration lines in the automotive industry, that measures the level of leakage present in the lines. The leak detection is carried out with working pressure (40 bar). This puts high pressure loads on the sealing tools for this test unit. The tester is fed manually with the test pieces. The helium test gas method with detection via mass spectrometer is used. The test gas is recovered after each test has been completed.

Test Piece

The pieces to be tested are flexible refrigeration lines, which are about 2 meters long. The lines are sealed on both sides and filled with helium on the inside. Via a vacuum, which is created on the outside of the lines, the penetration of test gas through the walls of the refrigeration lines can be measured. Two lines are tested at the same time during one test cycle.

- Leak Rate: Range 10E-6 ccm/sec

- Production Cycle: 150 parts/hour

- Test piece volume: 1 liter

- Test Pressure: 40 bar

- Test Gas: Helium-Air

Our References

- OEMs

- Automotive Companies

- Suppliers worldwide

Your Advantages

- State-of-the-Art Fabricating Machinery

- Fabrication based on your Samples, Instructions or Drawings

- Reliable and High Quality Production

- Quick Processing

W. v. d. Heyde GmbH – Leak Detection Technology

Wetternstraße 2 | 21682 Stade | Telefon:

+49-4141-9991-0 | Fax: +49-4141-2871

E-Mail: info@vdh-germany.de

W. von der Heyde GmbH

Wetternstraße 2

21682 Stade

Phone: +49-4141-9991-0

Fax: +49-4141-2871

E-Mail: info@vdh-germany.de

VDH US, INC.

PO Box 1623 Millersville, MD 21108 | USA Phone: (00) 1-410-729-1288 Fax: (00) 1-410-729-1023 E-Mail: info@vdh-us.com

Internet: www.vdh-us.com